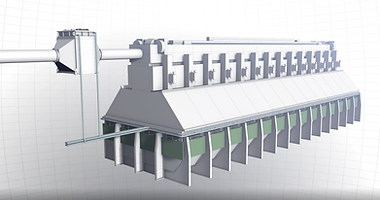

Heat losses from Primary Aluminium cell.

Cronus Energy Recovery & Production modulation

During aluminium production, it is important to keep the cell in thermal balance. This required:

- a predetermined power input,

- a stable chemical process

- a steady ambient temperature

The cell must have a stable thermal balance to achieve the most efficient production.

In order to achieve thermal balance, about 50% of the applied energy is lost to the surroundings (mostly through the sidewalls and the exhaust duct).

Cronus has developed a unique technology for active cooling/heat recovery of the aluminum cell. Cronus especially designed heat-exchanger are based on heat-pipe technology and they are located on the outside of the sidewall and on the off-gas duct.

By using heat pipe and the active cooling technology, Cronus solution gives the aluminium producer full control over the thermal balance of the cell which makes possible to modulate the aluminium production rate by +/- 20% while keeping the cell safe.

Heat pipe technology

Heat pipes are usually used for cooling of electronics at lower temperature but Cronus developed its heat exchangers to fit to most of energy demanding application where heat is lost through the process.

After recovery of the heat from the process, this energy can be re-utilize in other processes/applications (more info).